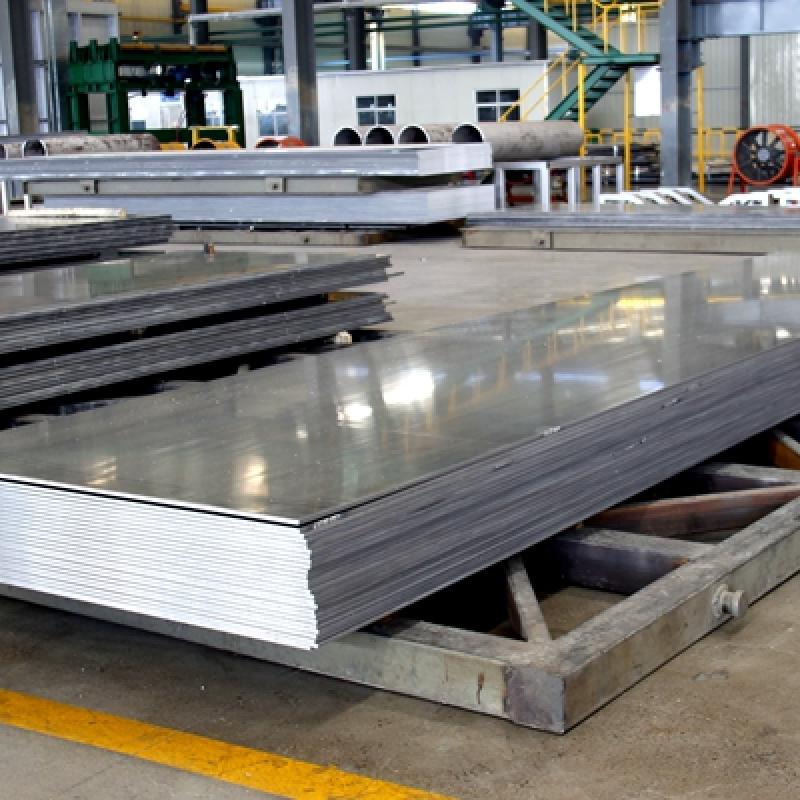

Aluminum plate,Aluminum coil,High quality aluminum oxide sheet.Aluminum oxide plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamps and lighting, consumer electronics, crafts, household appliances, interior decoration, signs, furniture, automotive decoration and other industries.The anodic aluminum plate is oxidized to form a thin layer of alumina on the surface, the thickness of which is 5~20 microns, and the hard anodic film can reach 60~200 microns.

Contact Now

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

Contact Now

Typical alloy 5052 aluminum plateMaterial state F, O, H12, h14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114Thickness (mm): 0.1-600Width (mm) 20-2650Length (mm): 500-16000Typical products: aluminum oxide plate, stock bin, automobile aluminum plate, mold, mask machine, electronic stamping parts, can lid, etc

Contact Now

Application scopeAnodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.Advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed.

Contact Now

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

Difference between aluminum oxidation and non oxidation:1. Oxidized aluminum will form a dense oxide film on the surface of the base, so the corrosion resistance will increase, and the melting boiling point will also increase. It can be used as a heat-resistant material, while non oxidized aluminum does not have these properties.2. Oxidized aluminum has a layer of oxide film, so it is corrosion-resistant and has more stable chemical properties than aluminum. In addition, aluminum can release hydrogen when it reacts with acid and alkali, and alumina has no gas.3.

Contact Now

Anodized aluminum plate is to place the aluminum plate in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and conduct electrolysis under specific conditions and applied current. Chemical aluminum oxide plate is a treatment process in which part of the base metal reacts in weak alkaline or weak acidic solution to thicken the natural oxide film on its surface or produce some other passivation films.

Contact Now

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.advantage(1) Good processability: the positive aluminum oxide plate has strong decorative property, moderate hardness, can be easily bent and formed, and can be continuously and rapidly punched, which is convenient for direct processing into products without complicated

Contact Now

The company mainly deals in: aluminum plate, patterned aluminum plate, alloy aluminum plate, thermal insulation aluminum plate, aluminum oxide plate, brushed aluminum plate, color coated aluminum plate, aluminum coil, aluminum rod, aluminum tube, aluminum strip, aluminum foil and other products. Now the company has hot rolling production line, casting production line, cold rolling production line, shear machine, annealing furnace and other equipment. The company has passed the ISO9001:2000 system certification.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is formed on the surface. The anodized aluminum plate improves its hardness and wear resistance, good heat resistance, the melting point of hard anodized film is up to 2320k, excellent insulation, breakdown voltage resistance is up to 2000V, enhances the corrosion resistance, and does not corrode in high-strength salt spray for thousands of hours. There are a large number of micropores in the thin layer of oxide film, which can absorb various lubricants and is suitable for manufacturing engine cy

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is formed on the surface. The anodized aluminum plate improves its hardness and wear resistance, good heat resistance, the melting point of hard anodized film is up to 2320k, excellent insulation, breakdown voltage resistance is up to 2000V, enhances the corrosion resistance, and does not corrode in high-strength salt spray for thousands of hours. There are a large number of micropores in the thin layer of oxide film, which can absorb various lubricants and is suitable for manufacturing engine cy

Contact Now

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in various states after the production of these alloys, the machining characteristics change greatly, which requires special machine tools or technologies.FormabilitySpecific tensile strength, yield strength, ductility and corresponding work hardening rate dominate the change of allowable deformation.RecyclabilityAluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is only inferior to silver, copper and gold. 3.

Contact Now

Chengye plate aluminum wafer has some advantages:1. Excellent elongation and tensile strength;2. Good processing performance, high stamping and stretch forming performance;3. Gas welding, hydrogen welding, resistance welding and brazing;4. High plasticity, conductivity and thermal conductivity;5.

Contact Now

"Aluminum wafers aluminum wafers are widely used in electronics, daily chemicals, medicine, culture and education, and auto parts. Electrical appliances, thermal insulation, machinery manufacturing, automobile, aerospace, military industry, mold, construction, printing and other industries. Such as kitchen utensils such as non stick pots, pressure pans, and hardware supplies such as lampshades, water heater shells, and stretching tanks, it is one of the largest aluminum alloy plate and strip deep processing products."

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent.

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is shaped at the surface. The anodized aluminum plate improves its hardness and put on resistance, properly warmness resistance, the melting factor of difficult anodized movie is as much as 2320k, first rate insulation, breakdown voltage resistance is as much as 2000V, complements the corrosion resistance, and does now no longer corrode in high-electricity salt spray for hundreds of hours.

Contact Now

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contact Now

Al Mn series alloy is one of the most widely used antirust aluminum. This alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, and cannot be strengthened by heat treatment. It has good plasticity during semi cold work hardening, low plasticity during cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing.

Contact Now

Basic InstructionAluminum coil also can be known as antirust aluminum coil. The manufacturing method of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is especially composed of manganese. The content material is among 1.0-1.5. It is a chain with exact antirust function. It is usually utilized in humid environments consisting of air conditioner, fridge and vehicle bottom. The rate is better than one thousand collection.

Contact Now

Aluminum wafers are very common in our life. Aluminum wafers can be found in can sealing, non stick pot bottom, traffic signs, lamp covers, and so on. In addition, aluminum wafers are also frequently used in mechanical manufacturing, automobile and other industrial fields. Therefore, when purchasing aluminum wafers, the primary consideration is the use. The use determines whether to purchase hot rolled or cast rolled materials.

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production technique of 3000 series aluminum coil in China is quite simple. 3000 series aluminum coil is mainly composed of manganese. The content material cloth is amongst 1.0-1.5. It is a series with actual antirust function. It is generally applied in humid environments which includes air conditioner, refrigerator and car bottom. The fee is higher than a thousand series. It is a extra generally used alloy series.

Contact Now