Al Mn series alloy is one of the most widely used antirust aluminum. This alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, and cannot be strengthened by heat treatment. It has good plasticity during semi cold work hardening, low plasticity during cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing.

Contact Now

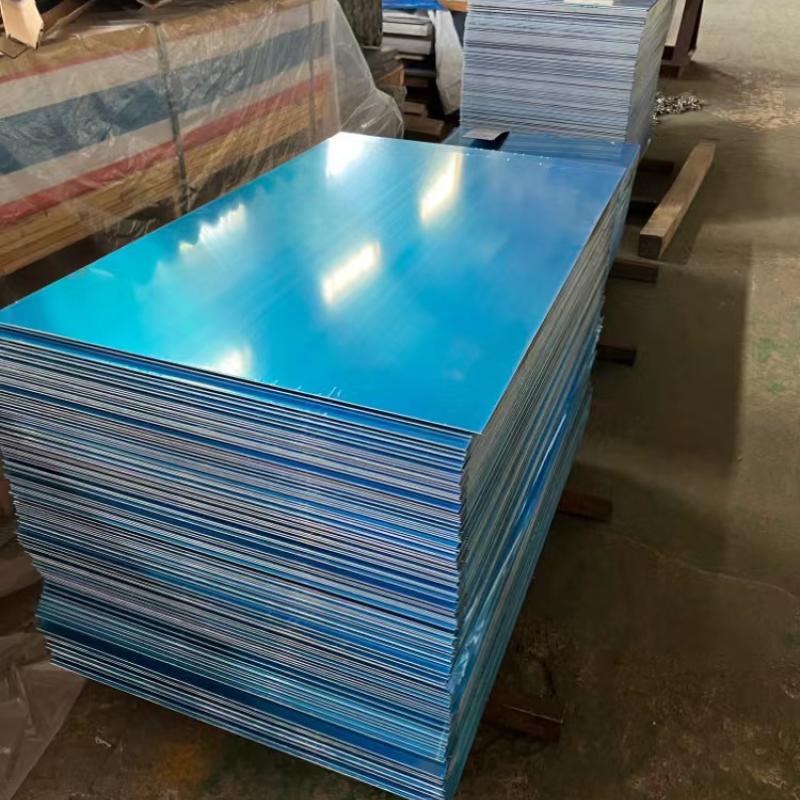

3003 antirust aluminum coil plate has high aluminum content and smooth surface.

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production technique of 3000 series aluminum coil in China is quite simple. 3000 series aluminum coil is mainly composed of manganese. The content material cloth is amongst 1.0-1.5. It is a series with actual antirust function. It is generally applied in humid environments which includes air conditioner, refrigerator and car bottom. The fee is higher than a thousand series. It is a extra generally used alloy series.

Contact Now

Basic InstructionAluminum coil also can be known as antirust aluminum coil. The manufacturing method of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is especially composed of manganese. The content material is among 1.0-1.5. It is a chain with exact antirust function. It is usually utilized in humid environments consisting of air conditioner, fridge and vehicle bottom. The rate is better than one thousand collection.

Contact Now

Patterned aluminum roll orange peel aluminum roll: patterned orange peel roll processed with 1060 Aluminum plate as the plate base, which can adapt to ordinary environment and is low in price. This pattern of aluminum coil is usually used in cold storage, floor and outer packaging.Patterned aluminum roll orange peel aluminum roll is also known as antirust aluminum plate. Its strength is slightly higher than that of ordinary aluminum alloy patterned coil, and it has certain antirust performance. However, its hardness and corrosion resistance are not up to 3000 series patterned plate.

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing method of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is in particular composed of manganese. The content material cloth cloth is among 1.0-1.5. It is a chain with actual antirust function. It is generally carried out in humid environments consisting of air conditioner, fridge and car bottom. The rate is better than one thousand collection.

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production gadget of 3000 series aluminum coil in China is particularly simple. 3000 series aluminum coil is specifically composed of manganese. The content material fabric is amongst 1.0-1.5. It is a sequence with correct antirust function. It is commonly applied in humid environments which incorporates air conditioner, refrigerator and car bottom. The price is higher than one thousand series. It is a more commonly used alloy series.ApplicationPacking

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production technique of 3000 series aluminum coil in China is quite simple. 3000 series aluminum coil is mainly composed of manganese. The content material cloth is amongst 1.0-1.5. It is a series with actual antirust function. It is generally applied in humid environments which includes air conditioner, refrigerator and car bottom. The fee is higher than a thousand series.

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production gadget of 3000 series aluminum coil in China is particularly simple. 3000 series aluminum coil is specifically composed of manganese. The content material fabric is amongst 1.0-1.5. It is a sequence with correct antirust function. It is commonly applied in humid environments which incorporates air conditioner, refrigerator and car bottom. The price is higher than one thousand series. It is a more commonly used alloy series.ApplicationPacking

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing machine of 3000 collection aluminum coil in China is in particular simple. 3000 collection aluminum coil is specially composed of manganese. The content material fabric material is among 1.0-1.5. It is a chain with accurate antirust function. It is normally carried out in humid environments which includes air conditioner, fridge and automobile bottom. The rate is better than a thousand collection. It is a greater normally used alloy collection.ApplicationPacking

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing device of 3000 collection aluminum coil in China is in particular simple. 3000 collection aluminum coil is in particular composed of manganese. The content material fabric material is among 1.0-1.5. It is a series with accurate antirust function. It is usually implemented in humid environments which includes air conditioner, fridge and vehicle bottom. The fee is better than a thousand collection. It is a greater usually used alloy collection.ApplicationPacking

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing technique of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is mainly composed of manganese. The content material cloth material is among 1.0-1.5. It is a sequence with authentic antirust function. It is usually implemented in humid environments which include air conditioner, fridge and vehicle bottom. The price is better than one thousand collection.

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production approach of 3000 series aluminum coil in China is quite simple. 3000 series aluminum coil is particularly composed of manganese. The content material fabric is amongst 1.0-1.5. It is a series with genuine antirust function. It is normally applied in humid environments inclusive of air conditioner, refrigerator and automobile bottom. The charge is higher than a thousand series.

Contact Now

3003 anti rust aluminum plate: mainly al Mn and Al Mg alloys. Because its aging strengthening effect is not obvious, it is not suitable for heat treatment strengthening, but the strength and hardness can be improved by work hardening. The main performance characteristics of this kind of alloy are medium strength, good plasticity and corrosion resistance, so it is called antirust aluminum, with good weldability.

Contact Now

Basic InstructionAluminum coil also can be known as antirust aluminum coil. The manufacturing manner of 3000 collection aluminum coil in China is quite simple. 3000 collection aluminum coil is particularly composed of manganese. The content material is among 1.0-1.5. It is a sequence with proper antirust function. It is generally utilized in humid environments along with air conditioner, fridge and vehicle bottom. The fee is better than a thousand collection. It is a extra generally used alloy collection.PackingApplicationSupport processing customization.

Contact Now

1. Pure aluminum plate: Material: 1050 / 1060 / 1070 / 1100 thickness: 0.1-500mm width: 10-2200mm2. Alloy aluminum plate: Material: 3003 / 5052 / 5754 / 5083 / 6061 / 6063 / 6082 / 7075 / 8011 thickness: 0.2-500mm width: 800-2800mm3. Curtain wall leveling aluminum plate: Material: 1060 / 1100, thickness: 0.95, 1.35, 1.5, 1.85, 2.0, 2.35, 2.5, 2.7, 2.85, 3.0mm, width: 800-1500mm2、 Aluminum coil: | aluminum foilMaterial: 1060 / 1100 / 8011 / 3003 / 3004 / 5052 thickness: 0.1-10mm width: 600-2000mm1.

Contact Now

Basic InstructionAluminum coil can also be called antirust aluminum coil. The production process of 3000 series aluminum coil in China is relatively simple. 3000 series aluminum coil is mainly composed of manganese. The content is between 1.0-1.5. It is a series with good antirust function. It is commonly used in humid environments such as air conditioner, refrigerator and car bottom. The price is higher than 1000 series. It is a more commonly used alloy series.PackingApplicationSupport processing customization. Consult the manufacturer for price and attribute details.

Contact Now

1. Light weight and high strength Ruiqiao aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) is made of high-quality aluminum coil material, with a density of only one-third of that of steel, light weight and high strength. 2. Good weather resistance Aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) has good corrosion resistance, waterproof and moisture-proof, maintenance free and service life of more than 10 years. 3.

Contact Now

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contact Now

Electrolytic zinc cathode plateEnergy saving electrolytic zinc cathode plate is composed of aluminum beam, aluminum plate and conductive clamp.

Contact Now

Basic Instruction1060 aluminum plate is broadly used in products with low electricity necessities.

Contact Now

Basic InstructionAluminum plate refers to the rectangular aluminum plate made of pure aluminum or aluminum alloy through pressure processing (shearing or sawing) to obtain rectangular cross section and uniform thickness Internationally, it is customary to call aluminum materials with thickness of more than 0.2mm, less than 500mm, width of more than 200mm and length of less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of less than 200mm as row or strip (of course, with the progress of large equipment, there are more rows with a maximum width of 6

Contact Now

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

Application scopeAnodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.Advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed.

Contact Now