Aluminum plates are generally divided into the following two types:1.

Contact Now

The company's prompt delivery, high quality and low price, service and thoughtful. the special size can be customized according to customer requirements processing, complete specifications, the lowest price, factory direct sales, quality assurance, delivery: seven days or so.Production site: Shandong province Pingyin County village north hole aluminum plantPhone: 15064183919Biography: 0531-87886769Web site: www.sdalcoa.com

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical characteristics of the production line:1. CNC is fully automatic. This production line starts from uncoiling of coiled materials to the completion of blanking of the whole roll of materials.

Contact Now

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.advantage(1) Good processability: the positive aluminum oxide plate has strong decorative property, moderate hardness, can be easily bent and formed, and can be continuously and rapidly punched, which is convenient for direct processing into products without complicated

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is only inferior to silver, copper and gold. 3.

Contact Now

Pure aluminum plate (the composition is basically rolled from pure aluminum)Alloy aluminum plate (consisting of aluminum and auxiliary alloys, usually aluminum copper, aluminum manganese, aluminum silicon, aluminum magnesium, etc.)Composite aluminum plate or brazing plate (aluminum plate material for special purpose is obtained by means of composite of multiple materials)Aluminum clad aluminum plate (aluminum plate is coated with thin aluminum plate for special purposes)2.

Contact Now

Pressed aluminum plate manufacturers,High quality molded aluminum sheet,Global delivery.Alloy aluminum watts, color aluminum tiles, antique tiles, corrugated aluminum plate, nano tile, commonly used specifications, 840, 750, 850, 900, etc., conventional thickness 0.5 mm0.6 mm0.7 mm0.8 mm0.9 mm1mm1. 2 mm1.

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is only inferior to silver, copper and gold. 3.

Contact Now

The patterned aluminum plate is a common material at present, which can be used in many places, including home decoration and household appliances. The wide application of aluminum plate is inseparable from its characteristics. There are many kinds of aluminum plates in our daily life. What are the advantages of patterned aluminum plates? The following five points can be summarized.1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high.

Contact Now

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contact Now

1. Thermal insulation aluminum coil has beautiful and durable functionsThe thermal insulation data can be closely linked with the decoration surface data, so the problem that the thermal insulation data cannot be closely linked with the decoration surface data has been solved. It is not easy to drop or loosen after contact, and the wind pressure resistance of the decoration surface data has been enhanced. The decoration surface has diversified colors, and can be processed into a forest of plates, which can better represent the characteristics of construction and decoration2.

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7g /, about 1 / 3 of that of iron or copper. Aluminum and aluminum alloy have high strength. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is second only to silver, copper and gold. 3.

Contact Now

Basic InstructionAluminum coil is widely used in electronics, packaging, construction, machinery and so on. What are the uses of aluminum coils? What are the classifications of aluminum coils? Aluminum coil manufacturers answer your questions and solve your doubts. We are a comprehensive enterprise specializing in the production, sales and transportation of non-ferrous metals.

Contact Now

How to judge the quality of aluminum brick 1. Observe whether there are multiple scratches on the surface of the aluminum corrugated plate. Aluminum ceramic tile belongs to mechanical processing, which will inevitably lead to some scratches and scratches, but if it is too much, the beauty will be affected. Friends who have high requirements for the surface of aluminum ceramic tiles can also ask the manufacturer to carry out film coating processing in advance. 2.

Contact Now

Basic InstructionAluminum coil is widely used in electronics, packaging, construction, machinery and so on. What are the uses of aluminum coils? What are the classifications of aluminum coils? Aluminum coil manufacturers answer your questions and solve your doubts. We are a comprehensive enterprise specializing in the production, sales and transportation of non-ferrous metals.

Contact Now

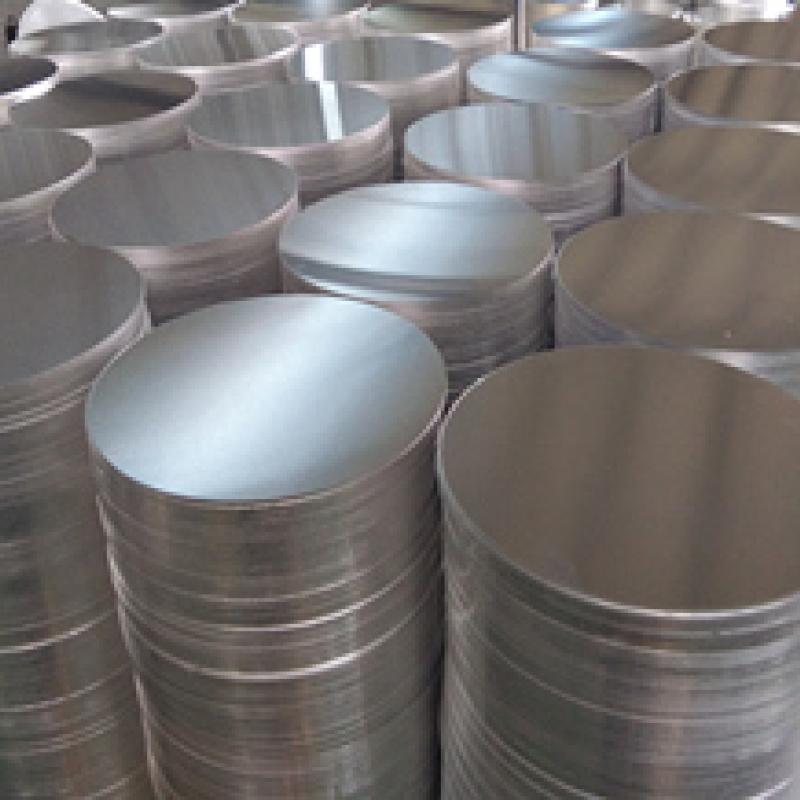

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is formed on the surface. The anodized aluminum plate improves its hardness and wear resistance, good heat resistance, the melting point of hard anodized film is up to 2320k, excellent insulation, breakdown voltage resistance is up to 2000V, enhances the corrosion resistance, and does not corrode in high-strength salt spray for thousands of hours. There are a large number of micropores in the thin layer of oxide film, which can absorb various lubricants and is suitable for manufacturing engine cy

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.Installation lap diagramSpecification

Contact Now

Classification according to different aluminum sheet alloys1. Ordinary aluminum alloy pattern plate: the aluminum alloy pattern plate processed with 1060 aluminum plate as the plate base can adapt to the ordinary environment with low price. Usually, this kind of patterned aluminum plate is often used for cold storage, floor and outer packaging.2. Aluminum alloy pattern plate: It is processed with 3003 as the main raw material. This aluminum plate is also called rust proof aluminum plate, which is slightly stronger than ordinary aluminum alloy pattern plate and has a certain rust resistance.

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing technique of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is mainly composed of manganese. The content material cloth material is among 1.0-1.5. It is a sequence with authentic antirust function. It is usually implemented in humid environments which include air conditioner, fridge and vehicle bottom. The price is better than one thousand collection.

Contact Now

Basic InstructionAluminum coil is widely used in electronics, packaging, construction, machinery and so on. What are the uses of aluminum coils? What are the classifications of aluminum coils? Aluminum coil manufacturers answer your questions and solve your doubts.

Contact Now

Thermal insulation aluminum sheet is commonly used in several specifications, generally with a width of 1000mm-2000mm. Other widths are also used, but not particularly. The thickness of aluminum sheet is usually 0.3mm-1.0mm. The length of aluminum sheet is generally divided into two types, one is a large roll of about three tons, which is suitable for large-scale operation, and the other is a small roll of about 50 meters, which is suitable for use in a small space. It is very convenient for two people to use a roll weighing between 50kg and 80kg.

Contact Now

Orange skin pattern and diamond shaped aluminum alloy pattern coil: commonly used for packaging pipes or outer packaging.The orange peel aluminum alloy pattern coil is divided into: Classic orange peel pattern aluminum coil, and variant orange peel pattern aluminum coil (also known as insect pattern). Its surface is similar to orange peel pattern, so it can also be called orange peel pattern aluminum plate.

Contact Now