Basic InstructionAluminum coil is widely used in electronics, packaging, construction, machinery and so on. What are the uses of aluminum coils? What are the classifications of aluminum coils? Aluminum coil manufacturers answer your questions and solve your doubts. We are a comprehensive enterprise specializing in the production, sales and transportation of non-ferrous metals.

Contact Now

Basic InstructionAluminum coil is widely used in electronics, packaging, construction, machinery and so on. What are the uses of aluminum coils? What are the classifications of aluminum coils? Aluminum coil manufacturers answer your questions and solve your doubts. We are a comprehensive enterprise specializing in the production, sales and transportation of non-ferrous metals.

Contact Now

1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high. After a certain degree of cold working, the matrix strength can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment. 2. Good conductivity The electrical and thermal conductivity of aluminum is only inferior to silver, copper and gold. 3.

Contact Now

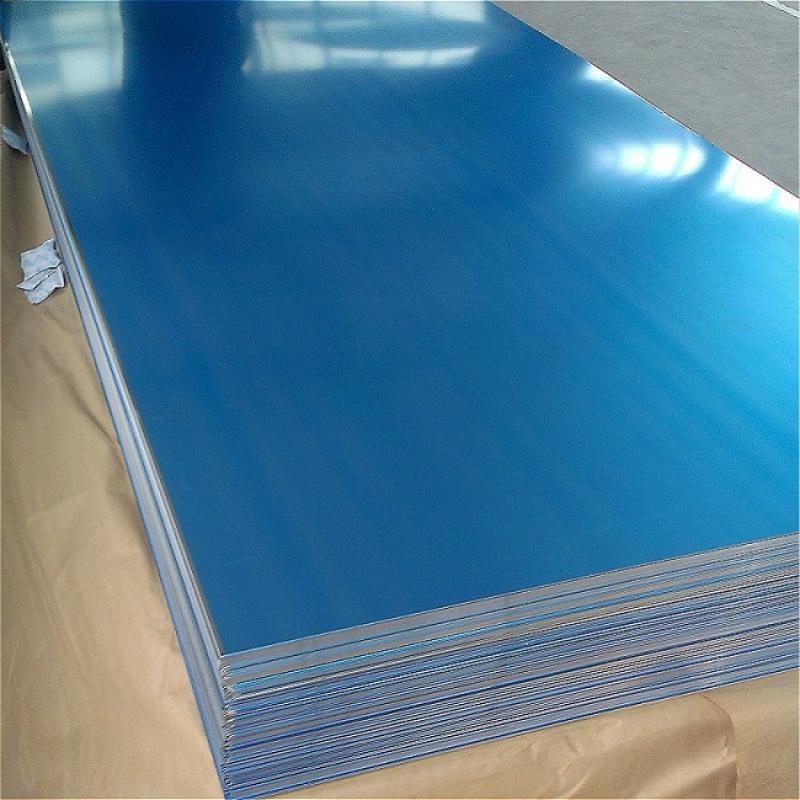

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contact Now

Basic InstructionAluminum coil is extensively utilized in electronics, packaging, construction, equipment and so on. What are the makes use of of aluminum coils? What are the classifications of aluminum coils? Aluminum coil producers solution your questions and remedy your doubts. We are a complete employer specializing withinside the production, income and transportation of non-ferrous metals.

Contact Now

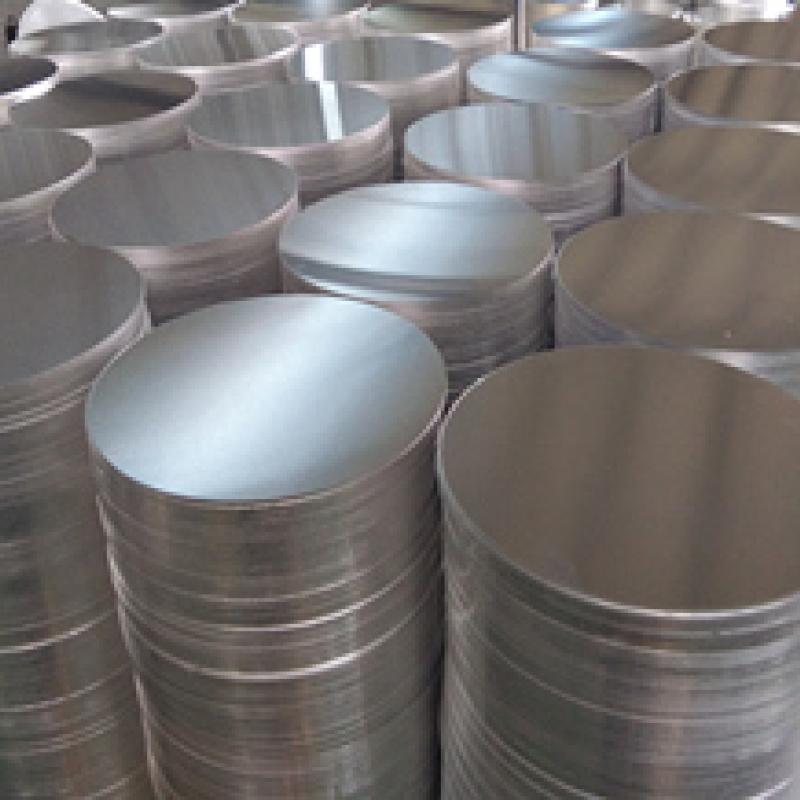

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical characteristics of the production line:1. CNC is fully automatic. This production line starts from uncoiling of coiled materials to the completion of blanking of the whole roll of materials.

Contact Now

The patterned aluminum plate is a common material at present, which can be used in many places, including home decoration and household appliances. The wide application of aluminum plate is inseparable from its characteristics. There are many kinds of aluminum plates in our daily life. What are the advantages of patterned aluminum plates? The following five points can be summarized.1. Low density The density of aluminum and aluminum alloy is close to 2.7 g, about 1/3 of that of iron or copper. The strength of aluminum and aluminum alloy is high.

Contact Now

Basic InstructionMachinabilityThe machinability of aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in various states after the production of these alloys, the machining characteristics change greatly, which requires special machine tools or technologies.FormabilitySpecific tensile strength, yield strength, ductility and corresponding work hardening rate dominate the change of allowable deformation.RecyclabilityAluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing device of 3000 collection aluminum coil in China is in particular simple. 3000 collection aluminum coil is in particular composed of manganese. The content material fabric material is among 1.0-1.5. It is a series with accurate antirust function. It is usually implemented in humid environments which includes air conditioner, fridge and vehicle bottom. The fee is better than a thousand collection. It is a greater usually used alloy collection.ApplicationPacking

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production technique of 3000 series aluminum coil in China is quite simple. 3000 series aluminum coil is mainly composed of manganese. The content material cloth is amongst 1.0-1.5. It is a series with actual antirust function. It is generally applied in humid environments which includes air conditioner, refrigerator and car bottom. The fee is higher than a thousand series. It is a extra generally used alloy series.

Contact Now

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is set 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, in addition to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contact Now

Classification according to different aluminum sheet alloys1. Ordinary aluminum alloy pattern plate: the aluminum alloy pattern plate processed with 1060 aluminum plate as the plate base can adapt to the ordinary environment with low price. Usually, this kind of patterned aluminum plate is often used for cold storage, floor and outer packaging.2. Aluminum alloy pattern plate: It is processed with 3003 as the main raw material. This aluminum plate is also called rust proof aluminum plate, which is slightly stronger than ordinary aluminum alloy pattern plate and has a certain rust resistance.

Contact Now

AI≈99.5% Si<0.2% Cn<0.04% Zn<0.04%比 重:2.7 g/cm3硬 度:65-125Hv规 格:φ0.6mm-φ2.0mm

Contact Now

Difference of alloy elements: 5052 alloy element is magnesium, while 6061 alloy element contains silicon in addition to magnesium. In addition, the processing state is different.

Contact Now

classificationThe grade of aluminum alloy is representative. The following is an example of 7075T651 aluminum plate grade. The first 7 represents the aluminum and aluminum alloy group - aluminum zinc magnesium alloy. Aluminum and aluminum alloy groups are divided into nine categories.

Contact Now

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contact Now

Pure aluminum plate (the composition is basically rolled from pure aluminum)Alloy aluminum plate (consisting of aluminum and auxiliary alloys, usually aluminum copper, aluminum manganese, aluminum silicon, aluminum magnesium, etc.)Composite aluminum plate or brazing plate (aluminum plate material for special purpose is obtained by means of composite of multiple materials)Aluminum clad aluminum plate (aluminum plate is coated with thin aluminum plate for special purposes)2.

Contact Now

Aluminum plate weight calculationAluminium sheet Panzhu has more rows of 600mm wide at most). Aluminum rod, diameter: 3-500mm aluminum tube, thickness: 2-500mm, it is the theoretical calculation formula of aluminum tube, aluminum plate and aluminum rod.

Contact Now

Basic InstructionAluminum coil additionally may be called antirust aluminum coil. The production technique of 3000 series aluminum coil in China is quite simple. 3000 series aluminum coil is mainly composed of manganese. The content material cloth is amongst 1.0-1.5. It is a series with actual antirust function. It is generally applied in humid environments which includes air conditioner, refrigerator and car bottom. The fee is higher than a thousand series.

Contact Now

Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pressure of press (KN): 1250160020002500Alloy stateMost of them are 1 series, 3 series, 5 series, 6 series and 8 series.The status is O, h, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 800010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (SPM): 40-55Nominal pres

Contact Now

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing technique of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is mainly composed of manganese. The content material cloth material is among 1.0-1.5. It is a sequence with authentic antirust function. It is usually implemented in humid environments which include air conditioner, fridge and vehicle bottom. The price is better than one thousand collection.

Contact Now

Aluminum wafers are mainly used in kitchenware production, sign making and other industries. The commonly used thickness is 1.0mm aluminum wafers and 1.2mm aluminum wafers. Among them, the kitchenware production industry has a large demand for aluminum wafers, especially in foreign countries. Because of its safety, lightness and easy processing, aluminum kitchenware products are more and more favored by customers. The 0.8mm aluminum wafers produced by Chaoyang Aluminum Co., Ltd. are hot rolled and cold rolled, of which 1060 Aluminum wafers and 3003 aluminum wafers are very popular.

Contact Now

Basic InstructionAluminum coil also can be known as antirust aluminum coil. The manufacturing manner of 3000 collection aluminum coil in China is quite simple. 3000 collection aluminum coil is particularly composed of manganese. The content material is among 1.0-1.5. It is a sequence with proper antirust function. It is generally utilized in humid environments along with air conditioner, fridge and vehicle bottom. The fee is better than a thousand collection. It is a extra generally used alloy collection.PackingApplicationSupport processing customization.

Contact Now

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contact Now